Once under NSDNR but kept out of the headlines, NS government support for development of a biorefinery shifted from NSDNR to Mines and Energy when DNR was split up and a new department of Lands and Forestry was announced (July 5, 2018)

Some of the history of Nova Scotia’s Plan B (what to do with “low value wood” if NP goes down). The focus of these items is on the Biorefinery and related concepts (Bioplastics, Biofuel, and Bioeconomy…) which have yet to be realized. View other subpages under BIOMASS/BIOFUELS & GHGs for more on direct burning of biomass for energy, which is already in place and being expanded in NS.

From Wikipedia:

A biorefinery is a refinery that converts biomass to energy and other beneficial byproducts (such as chemicals). The International Energy Agency Bioenergy Task 42 defined biorefining as “the sustainable processing of biomass into a spectrum of bio-based products (food, feed, chemicals, materials) and bioenergy (biofuels, power and/or heat)” [1]. As refineries, biorefineries can provide multiple chemicals by fractioning an initial raw material (biomass) into multiple intermediates (carbohydrates, proteins, triglycerides) that can be further converted into value-added products.[2]. Each refining phase is also referred to as a “cascading phase”.[3][4] The use of biomass as feedstock can provide a benefit by reducing the impacts on the environment, as lower pollutants emissions and reduction in the emissions of hazard products[5].

Energy debate heats up in Nova Scotia

The Canadian Press on CTV News Dec 21, 2009

Nova Scotia’s Biomass mess

By Chris Benjamin in the Coast, Jan 21, 2010. It references Wheeler, D., & Adams, M. (2009). Stake Holder Consultation Process for: A New Renewable Energy Strategy for Nova Scotia. Final Report to the Government of Nova Scotia. Halifax: Dalhousie University. Retrieved January 18, 2010, from

http://www.gov.ns.ca/energy/resources/EM/renewable/Wheeler-RenewableStakeholder-Consultation-Report.pdf. No longer available. I attempted to raise concerns about carbon neutrality of biomass and fragility of NS soils with Wheeler and others, but without avail: The Port Hawkesbury Biomass Project (2010): Concerns related to carbon emissions and impacts of harvesting on soil nutrients & acidification David Patriquin, Comments submitted to the Nova Scotia Utility and Review Board.

| Jonathan Porter

From Jon Porter linkedin.com page, under Experience: Executive Director, Renewable Resources, NS DNR, May 2014 to present; Consultant, JMP Consulting Services Sep 2013 to May 2014; Manager of Forestry and Fibre Resources at Renova Scotia Bioenergy Dec 2012 to Jun 2013; Manager of Forestry and Fibre Resources, Atlantic Region, Bowater Mersey Paper Company Ltd Nov 1980 to Dec 2012 Jonathan Porter of Beach Meadows, along with 11 other Nova Scotians, has been named by Natural Resources Minister John MacDonell to help guide the development of a new natural resources strategy for the province. The Roots of Sustainable Prosperity in Nova Scotia: A PANEL OF EXPERTISE REPORT ON FORESTS TO THE STEERING PANEL February 2010 by J. Porter. Amongst the recommendations: Complete biomass guidelines under the Code of Forest Practices, building on the draft prepared by department staff in 2009, which included guidelines for the retention of fine and coarse woody debris. The guidelines should incorporate the University of New Brunswick biomass model, which will provide a site-specific tool to identify where biomass removal is not appropriate. Balanced Budget 2013-2014:ReNova Scotia Bioenergy Incorporated N.S. rapped for hiring former Bowater manager in renewables role |

Former Bowater mill to become forestry innovation centre

CTV News Dec 12, 2012. “The former Bowater Mersey paper mill in southwestern Nova Scotia will be converted into a research, development and demonstration facility. Premier Darrell Dexter made the announcement today in Brooklyn, where he said his government was teaming up with private utility company Emera (TSX:EMA) and CelluFuel, a renewable energy company, to launch the site. The establishment of the centre comes after the government made a deal this week to acquire 220,000 hectares of land from Resolute Forest Products Ltd., the mill’s former owner, while taking on $117.7 million in debt. It also follows a recommendation made by a panel that examined how to revitalize the region’s economy after the paper mill shut down earlier this year, laying off 320 workers. Emera has signed on as the centre’s first tenant, promising to spend at least $1 million over the next five years. Innovacorp, a provincial Crown agency that focuses on venture capital investment, will spend up to $500,000 to cover start-up costs. The provincial government is also giving $500,000 to CelluFuel which is intended to help the company turn wood biomass into renewable diesel fuel.

Biofuel company, Emera setting up shop on mill site

Atlantic Farm Focus Dec 13, 2012 From the Intro: The Bowater mill site (in Brooklyn, Queen’s County, Nova Scotia) will soon see activity again, as two businesses take up tenancy. Cellufuel will be doing research and development, with plans to create a diesel biofuel demonstration plant with construction starting next Spring. The company hopes to produce around 1 million litres of biofuel through this process, employing five to 10 people.

Biofuel project set to fire up in February after provincial loan

Chronicle Herald Aug 30, 2013. No longer available; from the Intro: “A Queens County pilot project to convert wood into biofuel aims to be up and running by February after getting additional help from the province. Cellufuel Inc. is receiving a $1.5-million loan to help build its demonstration project in Brooklyn, near Liverpool. The province, which announced the funding Friday, also gave the project $500,000 in December for startup costs. “We’ve been very active and it seems that we’re able now to take this next step, which is fantastic,” Cellufuel president Chris Hooper said in an interview.”

Biofuel pilot plant planned for site of former Bowater Mersey mill

Pulp and Paper Canada Sep 17, 2013. “A pilot project to convert wood into biofuels has plans to be operational by next February after getting loans from the province of Nova Scotia. The Chronicle Herald reported Aug. 30 that Cellufuel Inc. is receiving a $1.5-million loan to help build its demonstration project at the site of the former Bowater Mersey mill in Brooklyn, N.S. The $4-million plant is part of a bioenergy and forestry innovation centre. Cellufuel president Chris Hooper told the newspaper the company has secured the remaining $2.5 million needed for the pilot project from private investors.’Cellufuel expects to use about 6,000 green tonnes of fibre a year in the demonstration phase. The fuel that’s produced will mostly be sold to oil companies in Nova Scotia and Brunswick. According to the newspaper, Cellufuel’s goal is to commercialize its licensed technology by launching 10 plants in the next five or six years. Hooper and fellow forest industry veterans Tor Suther, Veselin Milosevic and Ed McKay hope their company will produce 200 million litres of fuel and generate $200 million in revenue annually.

ENTREVESTOR: Cellufuel has potential to burn

Chronicle Herald Jan 14, 2013. No longer available. From the Intro: “Cellufuel’s plan to open a demonstration biofuel facility in Brooklyn, Queens County, this summer is just the first step of an ambitious industrial enterprise intent on having 10 plants within five to six years producing $200 million in annual revenue. r. …Cellufuel now plans to open a demonstration facility in Brooklyn this summer, which will have a capacity to produce about one million litres of diesel annually. Given that this is the first biofuel plant to rely completely on wood as a feedstock, the founders hope it will validate the technology.”

Cellufuel looking forward to moving into Bowater site

NovaNewsNow.com, Feb 11, 2014

Jeff Bishop of Forest Products Association (now Forest Nova Scotia) talks to NS House of Assembly Committee on Resources, Mar 20, 2014

Covers a wide range of topics related to deregulation of , private woodlots, biomass/Cellufuel, transportation issues, red tape reduction “A few years back we had Peter Duinker and Bill Lahey with Dalhousie University look at the amount of red tape that is within our industry and what could possibly be done.” [Duinker, P.N. and W. Lahey. 2010. Optimizing the Regulatory Environment for the NS Forest-Products Sector: Phase-I Report. Faculties of Management and Law, Dalhousie University, Halifax, NS.]

Cellufuel gets half million federal loan; company plans to expand into Clare

Yarmouth Co. Vanguard Mar 21, 2014.

Halifax’s CelluFuel secures $5m to build plant

The Chronicle Herald, Sep 9, 2014. no longer available.

From the Intro: “CelluFuel Inc. of Halifax has raised $5 million in capital to build a demonstration-scale plant that will produce synthetic, renewable diesel fuel from wood biomass. “We are extremely pleased with the successful completion of our demonstration project funding effort and excited about the value our new investors bring to our business,” CelluFuel president and CEO Chris Hooper said in a recent news release. The company will build the plant at the province’s ReNova Scotia Bioenergy site in Brooklyn, Queens County, formerly Bowater Mersey Paper Co. Ltd. The site serves as a provincial demonstration centre for companies focused on bioenergy innovation.”

Nova Scotia Biomass Project Raising “Green,” Forest Industry Concerns

On www.naylornetwork.com/, Jan 15, 2015.

“A report this past week by the Herald News, Nova Scotia, Canada, shows chipped wood piled up, waiting to be burned at Nova Scotia Power’s biomass burning power generating station at Point Tupper, Richmond County, N.S. (see photo). About 2,790 hectares are currently “in use” for power generation. That’s a rough estimate of how much woodland will need to be cut annually to feed Nova Scotia Power’s biomass boiler at Point Tupper…Foresters in northern Nova Scotia are warning that the wood being burned at Nova Scotia Power’s new biomass boiler may be green, but the electricity coming out of it isn’t. The boiler, started by now-defunct NewPage Port Hawkesbury Corp. and sold to Nova Scotia Power, opened during the summer of 2013. Running at peak capacity, which it is a bit shy of now, it burns 670,000 “green” metric tons of wood fiber annually to produce 60 MW of electricity…According to Nova Scotia Power, half the boiler’s needs are fed by wood waste from Port Hawkesbury Paper, sawmills, and other woods operations. That leaves about 335,000 metric tons of sustainably marked forest that are cut to feed it. A rough industry average in northern Nova Scotia is that you get about 120 metric tons of wood fiber off a hectare. Divide 335,000 metric tons by 120 and you get 2,792 hectares getting cut every year for the foreseeable future to be burned for electricity in a furnace that works at about 74% efficiency. “You’ve got to be careful with averages,” Allan Eddy, associate deputy minister at the Natural Resources Department, warned late last week. “If you shoot two feet in front of a duck and then two feet behind a duck, on average, that duck is dead.”However, Eddy acknowledged that land is being cleared to feed the biomass boiler. “They’re going after anything they can get their hands on to feed that thing,” Phil Clark, an Antigonish County sawmill operator, said late this past week. “They’re laying places to waste to feed it.”

Cellufuel turns lumber into renewable biofuel

Stephanie vanKampen · CBC News Sep 11, 2015

Biomass, Freedom of Information, and the Silence of the DNR Company Men

Linda Pannozzo in the Halifax Examiner on April 6, 2016

Bio-based fuels from our forests?

NSFN July 7, 2016

Big announcement today, with taxpayer dollars going to study “innovative uses of [Nova Scotia] forest products and new market opportunities…Being studied are things including new market opportunities and alternatives for petroleum products with bio-based fuels in marine diesel and heating oil applications. Another initiative is looking at how forestry contractors can integrate technology, innovation and best practice to help improve their performance.”

BRIGHTON: LOTS OF QUESTIONS ABOUT NEW FORESTRY INNOVATION HUB

On https://www.workingforest.com July 11, 2016 (it’s a Chronicle Herald article no longer available as such). “Emera Inc. is sinking $1 million into a new forestry innovation “hub,” based in an Innovacorp office in Dartmouth. Provincial and federal government partners are jointly contributing another $667,000 to this enterprise. But what is this hub? Who, exactly, is receiving the money? And why is Emera investing so heavily? The provincial funding partners, which are the Department of Natural Resources and Innovacorp, declined to answer specific questions about the ownership model for this hub. So did Emera, the principal investor. A principal consultant to the project, Rod Badcock, said the government partners and Emera had formed a governance committee to guide the work, which was being done by an informal partnership, in which he plays a principal role. Badcock described the hub model as “flexible” and in a telephone interview he agreed it was not “straight-forward.” He said the two partners providing key services to the project were Bioapplied Innovation Pathways, which is itself a private partnership, and FPInnovations, a not-for-profit research institute serving the forestry industry in Canada. Bioapplied is a partnership between Badcock and Gregory Maloney and their respective companies: Fusion Intel Inc., registered in Nova Scotia, and Enoptec Inc., registered in Quebec. The hub project is just one of Bioapplied’s clients. Another client is CelluForce Inc., whose shareholders are the pulp and paper company, Domtar Corp.; Schlumberger Limited, a global technology company serving the oil and gas sector; and FPInnovations. CelluForce supplies wood-based cellulose nanocrystals, or nanocrystalline cellulose, for industrial products. One the objectives of the hub partners is to find domestic markets for new industrial products, such as biofuel, which may be processed from wood fibre. Emera, which indirectly owns the province’s two major biomass plants, seems attracted to the commercial prospects for diverting low grade wood to higher value products at a time when there is less demand for burning biomass to produce electricity…”

Progress Report did not highlight key priorities in NSDNR Business Plan

NSFN Sep 2, 2016

It’s curious (and concerning) that the recently released Progress Report on the 2011-2020 Natural Resources Strategy and the related Press Release dwell on feel-good items such as the Community Forest, establishing a Forest Biodiversity Science Advisory Committee and a new forest operating agreement with Mi’kmaq but fail to mention the first two of five priorities for forests cited under the NSDNR Business plan for 2016-2017:

– Complete projects to assess the current state of Provincial fibre supply/cost and identify/qualify target markets for biorefinery products, in collaboration with provincial, federal and private sector partners.

– In collaboration with other government departments and agencies, engage with targeted companies to attract biorefinery investment to Nova Scotia.

Innovation Hub Makes First Year Progress

NSDNR Press Release Jan 26, 2017. “A new study shows Nova Scotia has strong potential to develop an innovative biorefinery that produces an alternative fuel from renewable sources of fibre.”

Value Proposition for a Biorefinery Sector in Nova Scotia

BioApplied & FPInnovations, Jan 2017.

“The emerging global bio-economy presents an opportunity for Nova Scotia’s renewable bioresource sector (forest, agricultural, ocean, and municipal solid waste). Nova Scotia is well positioned to lead in providing low-carbon solutions that will also enhance economic prosperity within the province. Across Canada, forest industries have entered an unprecedented period of structural change. Within Nova Scotia, the right actions must be taken to nurture and support a successful and suitable transformation. Doing so, in concert with the entire bio-resource spectrum, will assure maximum value for all sectors. The creation of an Innovation Hub (iHub) is a first and critical step towards this outcome. The iHub will foster strong collaboration among all stakeholders. It will determine the primary actions required to establish a compelling value proposition to attract and support an industrial cluster of bio-based processing and manufacturing industries, including a liquid fuel biorefinery. Initially, five key areas have been considered of primary importance: feedstocks, supply chains, technology, markets, and funding. An initial undertaking was implemented to fully analyze and understand these categories, built around seven projects: Feedstocks, Bio-based Fuels, Industrial and Technological Benefi ts, Supply Chain, Dynamic Modelling, Operations and Outreach, and Governance.” Cites involvement of Alan Eddy and Jon Porter.

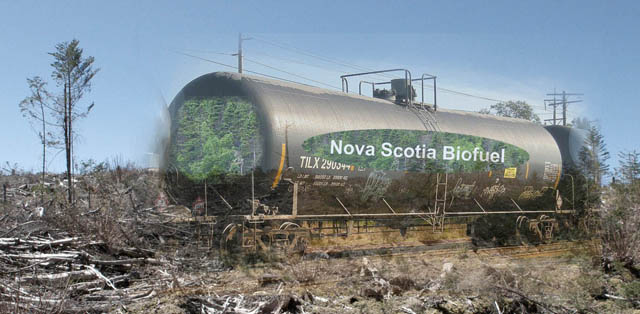

Nova Scotia’s Biorefinery Plan cites full-tree harvesting, other requirements to make it competitive

NSFN February 22, 2017.

“Nova Scotia’s Biorefinery Plan cites a condensed softwood sawmill industry, full-tree harvesting, a 2+% mandate for biodiesel, slacker Allowable Gross Vehicle Weight regulations to make it competitive, but is vague on role of primary forest biomass and short on carbon accounting; senior NSDNR bureaucrats have been directly involved in developing the plan.”

Are biofuels from Nova Scotia forests good for the environment? Show us the science!

May 4, 2017

Cellufuel “pauses” operations at its Brooklyn demonstration plant

Tim Bousquet in Halifax Examiner, Jul 28, 2017 “The start-up biofuel company has received at least $4.5 million in public money; the shut-down is temporary and just part how “innovation” works, insists president Chris Hooper.”

Cellufuel wants access to Nova Scotia’s “Inactive Forests”

August 2, 2017

Allan Eddy retains interests in biomass

NSFN May 11, 2018

While we wait for the Independent Review of Forest Practices in Nova Scotia, Port Hawkesbury Paper hires ex-DNR forest bioenergy advocate

NSFN Aug 15, 2018

Forest management group proposal for biomass heating provides an opportunity for Nova Scotia government to “get it right” on forest bioenergy

NSFN Sep 26, 2018

N.S. adjusts refinery environmental assessment regulations

Stuart Peddle in the Chronicle Herald Dec 11, 2018

Nova Scotia L&F searching for Manager, Innovation & Business Development

NSFN Dec 11, 2018

Reposting: Planning ahead for Industrial forestry in Nova Scotia – allowing bigger trucks on our roads

NSFN Jan 3, 2019

Nova Scotia L&F and Energy, take note: U.S. Securities and Exchange Commission petitioned to protect investors against misleading claims about biofuels and the like

NSFN April 11, 2019

Time for Nova Scotia Government to come clean on forest bioenergy feedstocks 19Mar2019

NSFN March 19, 2019

“It’s time for Nova Scotia political leaders to stop what seems to be a runaway, and rationally incoherent, biomass energy policy” 9July2019

NSFN July 9, 2018 citing editorial in Chronicle Herald

McNeil & Co firm on closure of Boat Harbour, vague on plan B (Biomass, Biofuel, Biorefinery and Bioeconomy)

NSFN Dec 14, 2019

Nova Scotia’s forestry sector future hinges on investment, innovation: Mill exec

Keith Doucette, The Canadian Press on BNN Bloomberg, Feb 12, 2020.

“Speaking to the industry’s annual general meeting Wednesday, Allan Eddy, manager of business development at Port Hawkesbury Paper LP, said the closure of the mill in Pictou County was like a large wave hitting the sector. Eddy likened the industry to a ship that’s been struck down but has the ability to right itself. “What’s creating the ship’s stability is the keel,” he said, referring to the structure along a vessel’s base. “In that context investment and innovation is what creates the keel for our sector and for our business … and that’s what gives us the ability to manage through the kinds of storms we are currently seeing.” He said Port Hawkesbury Paper is being driven by the low-carbon economy and constantly looking for ways to be more energy-efficient while developing new product lines in order to be competitive. The mill produces glossy paper for flyers and magazines and has recently produced a new kind of coated paper to help it compete in the U.S. market, Eddy said. He said it is also looking to create renewable fuels and fertilizer from the byproducts of its paper-making process. The mill is also looking to develop an eco-industrial park on its property where various businesses will be able to work in concert with the mill.”

Nova Scotia adding $13.5M to forestry transition fund

Taryn Grant, Michael Gorman · CBC News Feb 13, 2020 “…”Markets is the biggest thing right now for their chips at the sawmill,” Rankin said..He said they’d be looking at export markets and new, innovative ways of using wood chips…Innovation in the sector was at the heart of several presentations on the second day of Forest Nova Scotia’s annual general meeting…Allan Eddy, manager of business development for Port Hawkesbury Paper, talked about that mill’s plans for an eco-industrial park. The idea is to attract other businesses with similar interests to set up shop on the mill’s 120-hectare campus and be able to feed off one another for energy and other potential efficiencies…Beth MacNeil, assistant deputy minister of the Canadian Forest Service, said making that change will require all players in the sector and all levels of government to focus on how to diversify markets and products…She pointed to British Columbia, where in response to shrinking amounts of fibre, the industry has shifted to higher-value wood products. “Rather than the traditional sawlog industry, they’re looking at bioproducts: bioplastics, using biomass for heat, electricity [and] focusing on secondary marketing,” said MacNeil. She said those options could have potential in Nova Scotia, as could considering ideas in the context of using the forests to help transition to a low-carbon economy and address climate change. ”

Elmsdale Lumber’s Plan B: selling pellets will be the bridge until Northern Pulp reopens

JENNIFER HENDERSON in the Halifax Examiner Feb 14, 2020. Subscription required

Family Sawmill Owner Robin Wilber’s company strategy for dealing with the loss of the NP market for low value wood, and behind-the scenes efforts to help NP re-open.

“The exponential growth of the bioeconomy is a global threat. Instead of contributing to climate mitigation, bioenergy and ‘bio’ products keep energy generation locked-in to the carbon cycle, decrease the amount of land available for food crops, drive land-grabs, and decimate forests – our most efficient carbon sinks.” – Global Forest Coalition Also view – Bioeconomy Day of Action – 7 November 2018

Environmental Paper Network.